Why Umeken

We combine the time-tested expertise of Japanese traditional medicine and cutting-edge research to produce effective, high-quality wellness products.

Rooted in over 300 years of Japanese medicinal ball making

During the prime of the Edo period (1683 ~ 1867), the use of natural herbs and various ingredients to produce “medicine balls” was popularized in the Toyama prefecture of Japan. These medicinal balls were portable and greatly increased the quality and life span of those who took them. It was from the Edo period that the foundations of Japanese Traditional medicine were slowly perfected, and passed down carefully through generations.

A descendant of such a family, Mr. Shoichi Inagaki opened a small ball-making company in 1958. Holding steadfast to the centuries-old tradition of hand pressing every ball and using only the best ingredients, the company grew steadily. In 1978, a partnership was formed with Mr. Hidekazu Sakamoto to establish Umeken® Co, Ltd. in Osaka and a few years later, manufacturing base was set up in Toyama.

Innovating wellness products

We conduct rigorous research to continually improve our manufacturing process and create innovative products.

Patent for spirulina-manufacturing technique that maintains a high density of microelements.

Technique patent for manufacturing football-shaped pills that are easy to ingest

Technique patent for manufacturing fermented L-type lactic acid calcium balls

Technique for manufacturing kelp balls

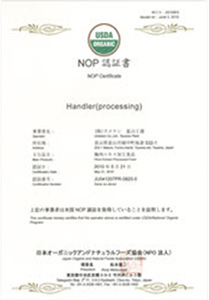

Ensuring safety and sanitation

Our products undergo strict FDA, USDA, and Health Canada entry reviews. Umeken manufacturing facilities are certified and regularly inspected by the Japan Health & Nutrition Food Association.

Practicing high

manufacturing standards

Practicing high

manufacturing standards

Each factory day begins with 2 hours of meticulous set up and ends with 2 hours of deep cleaning.

Employees change into new sterile clothes during their shift.

Each production room maintains its individual air pressure.